RFID solutions for Returnable Transport Item (RTI) management

Returnable Transport Items (RTIs) are essential elements in the logistical operations of numerous industries. These items, including containers, pallets, crates, barrels, etc., are used to transport and store products safely and efficiently. The key characteristic of RTIs is that, unlike single-use items, they are designed to be reused multiple times.

Efficient management of RTIs is crucial for several reasons. Firstly, they can represent a significant investment for companies, so their loss or damage can have a significant financial impact. Inadequate control of RTIs can lead to disruptions in logistical operations and hinder efficiency and productivity. Additionally, RTIs play a key role in the circular economy and sustainability efforts, so their efficient management is also important from an environmental perspective.

The challenges of RTI management: losses, tracking, damages, etc.

Efficiently managing RTIs is a complex task that presents several challenges. From loss and theft to tracking and optimization, companies often struggle to effectively handle these items.

The first challenge that many companies face is the loss of RTIs. Whether due to theft, losses in transit, or simply poor management, the loss of these valuable assets can have a significant impact on a company's bottom line. Another key point that companies must be able to control is the tracking of RTIs, which can be a complex task without the necessary tools. Each company may have thousands of these items in circulation, and accurately tracking where they are, how many are available, and when they need to be replaced or repaired can be a significant logistical challenge.

The solution: RFID Technology for RTIs

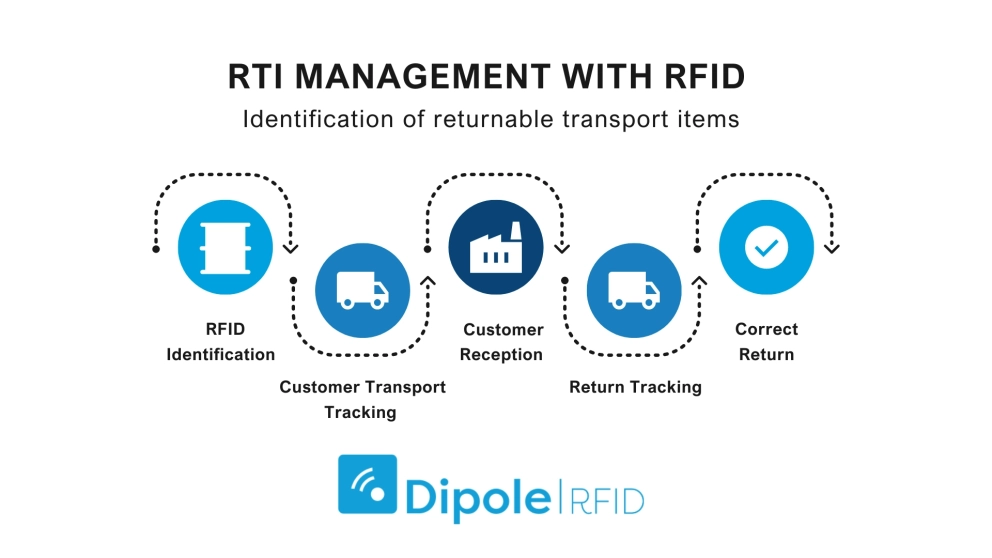

In the face of these challenges, radio frequency identification (RFID) technology presents itself as an effective and practical solution. By providing a way to identify and track RTIs accurately and in real-time, RFID can address many of the problems associated with managing these items.

Each RTI is equipped with an RFID tag that uniquely identifies it throughout its lifespan. Different elements can be used to identify the products, such as RFID tags with IP68 protection and special adhesives capable of withstanding harsh conditions, or hard tags made of even more durable materials, ideal for environments where returnable containers may be subjected to adverse conditions such as moisture, high temperatures, impacts, or vibrations. The choice depends on the specific needs of each client, which is why a preliminary study is essential to ensure proper detection and operation throughout the entire process and return of the RTIs.

RFID tags contain crucial information about the RTIs, including their location, status, when and where they have been used, and when they need to be replaced or repaired, among other data. All of this information can be accessed in real-time, improving management efficiency and reducing the chances of human error, as there is no need for manual recording of these status changes.

However, RFID tags alone cannot operate; they require RFID antennas and readers installed at strategic points to receive and process information. The antennas emit radio frequency signals that "wake up" the tags, which respond by sending the information stored in them. This information is captured by the readers and transmitted to the software, which is responsible for managing the received information.

Readers can be fixed, installed in specific locations such as warehouse entrances and exits, production lines, etc., or mobile, integrated into handheld devices such as PDAs or terminals, allowing readings to be taken at any point in the logistics process.

Finally, the RFID software collects, analyzes, and presents all this information in an accessible and useful format for decision-making. This software can be integrated with the company's existing systems, such as ERP or warehouse management systems, providing a unified and comprehensive view of the supply chain.

Benefits of implementing RFID in RTI management

Implementing RFID technology in RTI management can have several benefits:

- Reduction of losses and theft: By tracking RTIs in real-time, companies can minimize losses and quickly detect any attempted theft.

- Improved tracking: With RFID, companies can know exactly where their RTIs are at all times, which can facilitate planning and decision-making.

- Increased efficiency: By eliminating the need for manual counts and facilitating the location of RTIs, RFID can improve the efficiency of RTI management operations.

- Enhanced sustainability: By maximizing the reuse of RTIs and reducing the need for single-use packaging, RFID can help companies be more sustainable.

How we implement the RTI solution at Dipole RFID

At Dipole, we work with complete solutions for proper RTI management.

- RFID tags: Our RFID tags are durable and adaptable, capable of withstanding the demanding conditions of logistics and transportation. We offer a range of options, including different types of attachment, impact-resistant and vibration-resistant materials, and IP68 certifications for industrial use, to cover different needs and budgets.

- RFID antennas: An important part of the solution is the RFID antennas, which are responsible for transmitting waves to the tags and receiving them back to send them to the readers. Depending on each infrastructure, a specific type of RFID antenna or others will be recommended.

- RFID readers: Depending on the characteristics of each client, we offer a range of RFID readers, including fixed and portable readers, which can adapt to different environments and RTI management operations.

- RFID software: Our RFID software allows companies to collect, analyze, and utilize RFID data to improve RTI management. The software can be integrated with the company's existing systems to provide a complete solution.

Related products

Contact Form

We can help you?

Find the RFID product or solution that meets your business needs.

Ask us to help you find the right decision.