01

RFID Automotive

RFID technology is digitalising the industry by connecting all of its processes to reduce workload and automatically verify tasks. Car and component manufacturers use it to achieve greater efficiency and coordination in all stages of manufacturing.

By incorporating RFID technology into the car manufacturing process, we can have a precise inventory of all parts and we can see their location in real time, or if they are moving within the factory. This strengthens quality control as we can detect potential problems in the production chain before they happen.

We gain control over all components in the manufacturing process, from receiving the goods from the suppliers to delivering the final product.

02

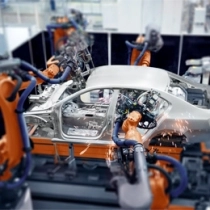

Moving the automotive industry towards industry 4.0

RFID technology drives the automotive sector towards industry 4.0 by connecting all processes and creating smart factories.

At Dipole, we design RFID solutions to the highest quality standards to ensure the most specific identification in any type of environment and meet all the needs of the automotive industry, from metal part identification, industrial paint treatment where tags are exposed to certain chemicals and manufacturing processes where very high temperatures are used.

Our solutions incorporate hardware, software and RFID tags that are resistant to all of these processes, whether high temperatures, chemicals or metal identification. This way we can guarantee total identification throughout the whole process.

03

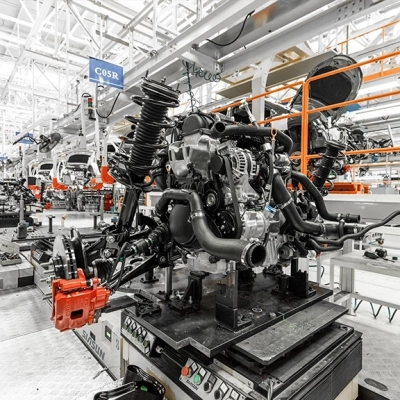

Automated component identification

Different components come from various suppliers during the manufacturing process, so they need to be correctly identified at all times with supplier, entry date and location, and we need to know in exactly which vehicle they are installed to be able to correctly trace them.

With RFID technology we can identify all kinds of automotive components such as seats, steering wheels, brakes, tyres, etc, that we need to be able to identify and associate with each of the finalised vehicles to ensure we meet all of the industry’s quality standards.

RFID management in the automotive industry

Identification

At Dipole, we have a wide range of tags designed for cars, such as metal tags, tags that are resistant to high temperatures or chemicals to be able to cover the whole identification process.

Detection

We install specific hardware for industrial environments to be able to detect everything that happens during the entire manufacturing process with maximum precision.

Management

Dipole develops its own software to manage all information generated by RFID in industrial environments in an easy, straightforward way.

Benefits of RFID technology in the automotive industry

Improvement and automation of inventories

Real-time management of all parts, both finished and in production

Identification of each article

Individual identification of each part and component

Precise information for decision making

RFID technology provides all the information needed to make better decisions

Reduction of costs and operating time

Removal of unproductive data and information entry work, reducing the associated costs.

Coordination of manufacturing flows

Maximum efficiency during production line stages by having information available on all processes

Real-time monitoring of location and movement of parts

Real-time recording of any movement within the plant

Control of incoming and outgoing parts and components

Total record of incoming materials from suppliers and outgoing materials to customers

Identification of finished parts

Total control when a part has been manufactured Complete record of all processes it has gone through

RFID technology for the automotive industry

Vehicle manufacturers

Component manufacturers

Logistics providers