RFID Technology for Industry 4.0

It is increasingly important for internal processes in industry to be better optimised and more efficient. Industry 4.0 promotes new production techniques using data and information provided by new technologies that complement company organisation, workers and assets.

Having access to precise information exactly when you need it is essential for industry development. This is why the fourth industrial evolution has transformed industry. The value offered by these data and how they are processed can give companies in these sectors greater production power and the ability to transform physical information into digital information.

The Fourth Industrial RevolutionRFID Technology for the Revolution 4.0

Each one of the industrial revolutions have brought about significant change for people’s lives. They are driven by innovation, generally leading to new and future technologies.

Companies and factories now have a new goal: retrieve data from all the processes occurring within processes. This revolution stands out from the previous ones, as it’s no longer just about smart and connected systems. It covers everything from genetic sequencing to nanotechnology, renewable energies to quantum computing. It relates to many aspects and tries to link them all together.

In conclusion, Industry 4.0 is growing rapidly. It provides factories with technology to automate processes and capture data. This digital transformation is changing all current production processes. It can provide real time data and information about the production processes of any business area.

RFID Technology for the Revolution 4.0

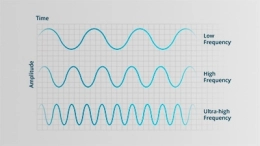

RFID technology is the perfect solution for automating processes in any industry. With radiofrequency identification, we can identify anything we want. It quickly and automatically retrieves all the related data, such as what or who has interacted with it, when, where, etc.

As previously mentioned, Industry 4.0 is made up of multiple pillars from different sectors. Let us explain some of the new technologies that are driving this new industry 4.0:

- Internet of Things (IoT): The Internet of Things (IoT) refers to the connection of physical devices, vehicles, buildings and other objects to the internet, allowing them to send and receive data and connect them all together. IoT is used in industry to improve efficiency, cut costs and boost productivity. For example, IoT sensors can monitor computer performance, process control systems can automate production and device connectivity can automate inventory management. Introducing RFID technology with IoT allows you to better monitor and analyse data, which in turn helps you make decisions based on such data and improve quality and efficiency.

- Big Data: aims to gather all of the data produced in a company’s industrial process. Big Data provides raw data, which then needs to be analysed to retrieve the most important information for the company. Software programmes are used to process this huge amount of data, analyse them in real time and present it in a practical format to be studied. All of this information can then be used to optimise processes within the company or factory.

- Cobots: Robots were one of the great advances of Logistics 4.0, and thus Industry 4.0. They can perform a wide range of tasks, including sorting and transporting heavy loads. Cobots (collaborative robots) are especially designed to interact in environments where they must work with humans. They are very useful as they optimise production and take monotonous or dangerous tasks off the hands of employees.

- The Cloud: is one of the pillars of the new Industry 4.0. It allows you to store a large amount of data and acts as a link between different sectors of the same company (engineering, supply chain, production, sales, distribution and services). It makes information analysis and processing more efficient and profitable. Well-managed cloud computing could also help to reduce startup expenses for small- and medium-sized companies. They can adjust it to their needs and expand as the business grows.

- Artificial Intelligence (AI): the fact that machines can “think for themselves” is an unprecedented level of technological independence. AI and machine learning enable companies to make use of all the data that the machines can retrieve from production plants and all of their business units (including from its partners and third-party stories).

Benefits of Industry 4.0

Industry 4.0 offers huge benefits for factory or company logistics processes:

- Integrate operations in real time: “Smart” factories process thousands of data in real time. This is one of the improvements provided by Industry 4.0 and the reason why many companies are moving towards this new type of industry. To be able to offer all the data requested, your factory needs technological tools such as RFID technology that can remotely monitor machines in real time.

- Create new business models: This new technology brings about a paradigm shift, opening up new business opportunities, even in traditional sectors such as the food sector.

- Reduce errors: By reducing human involvement in your processes, you reduce the probability of error in industrial operations. Now you can even programme machines to operate with minimal human interaction. All the data retrieved can be used to help detect errors that you may have otherwise missed and find a solution.

- Cut costs: Automating processes directly results in lower operational costs. By eliminating human error, you also reduce the related costs.

- Boost productivity: Automating processes increases the overall productivity of factories and companies. Think about all the time a professional has had to spend on a monotonous task that brings no added value to the company. Now they can spend that time on more complex, strategic tasks that are related to the core business and on activities that are related to the company’s goals, bringing added value to its results.

- Optimise efficiency: Obviously, most processes are automated when you move your industry to 4.0, which speeds up tasks and reduces errors in processes. Resources are used in a more responsible, intelligent and economical way. In the end, this results in increased operational efficiency and improvement in the business’ performance indicators.

We at Dipole encourage you to explore these technologies and learn how to integrate them into your business needs and strategies. This is why we are offering you all of our RFID intelligent identification services. With these solutions, you can provide real-time, reliable, live data and make sound decisions regarding your business. If you would like to learn more about our services, get in touch with us. You can also read more about new technologies on our blog.

Related products

Contact Form

We can help you?

Find the RFID product or solution that meets your business needs.

Ask us to help you find the right decision.